Release Agents / Form Oils

In the concrete precast industry, release agents play a crucial role in preventing concrete from adhering to the formwork, resulting in seamless and smooth releases of the finished product. Release agents are used to improve the quality and efficiency of precast production. They are beneficial due to their ability to reduce the risk of cracking, surface defects, and other issues associated with concrete adhering to formwork.

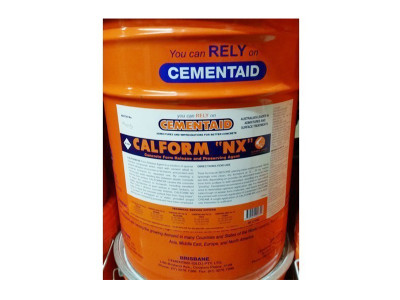

Oil-based release agents and water-based release agents are the most widely used release agents in the concrete precast industry. Oil-based release agents are usually made from petroleum or other oils and are easy to apply and long-lasting. Formwork and concrete can be separated by these barriers, preventing adhesion. Nevertheless, oil-based release agents are messy to use and are not eco-friendly.

There has been a surge in interest in water-based release agents due to their environmental benefits and improved health and safety standards. A thin film of these release agents is applied to the formwork as a thin mixture of surfactants and chemical additives. Many precast producers prefer them over oil-based release agents because they are safer to use and produce less waste.

Choosing the right release agent for the type of formwork and concrete mix is crucial, since not all release agents are appropriate for all applications. There are several factors to consider, such as the porosity of the formwork, the time the concrete takes to cure, and the ambient temperature and humidity. It is crucial to choose the right release agent to avoid problems such as surface defects, corrosion of formwork, and reduced concrete strength.